Slide 1

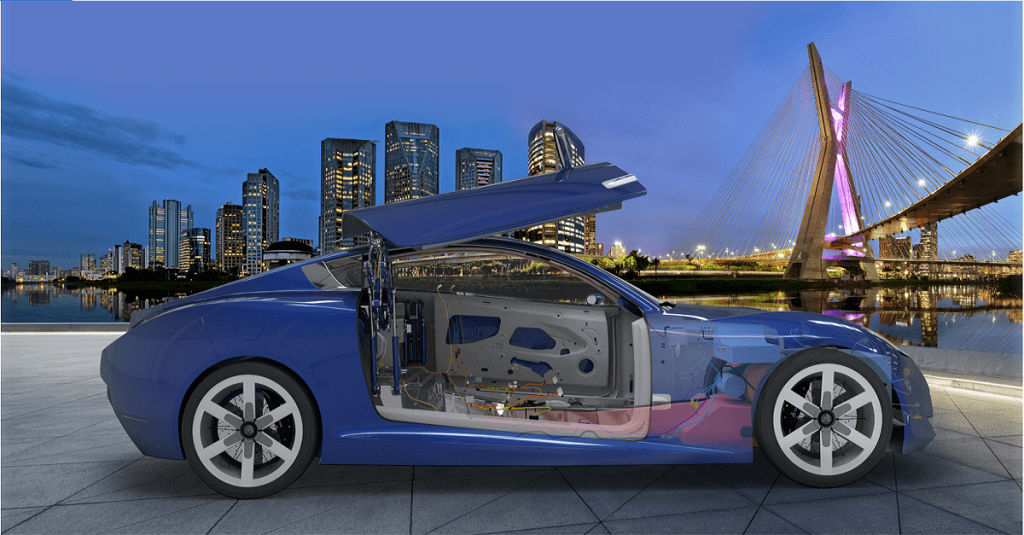

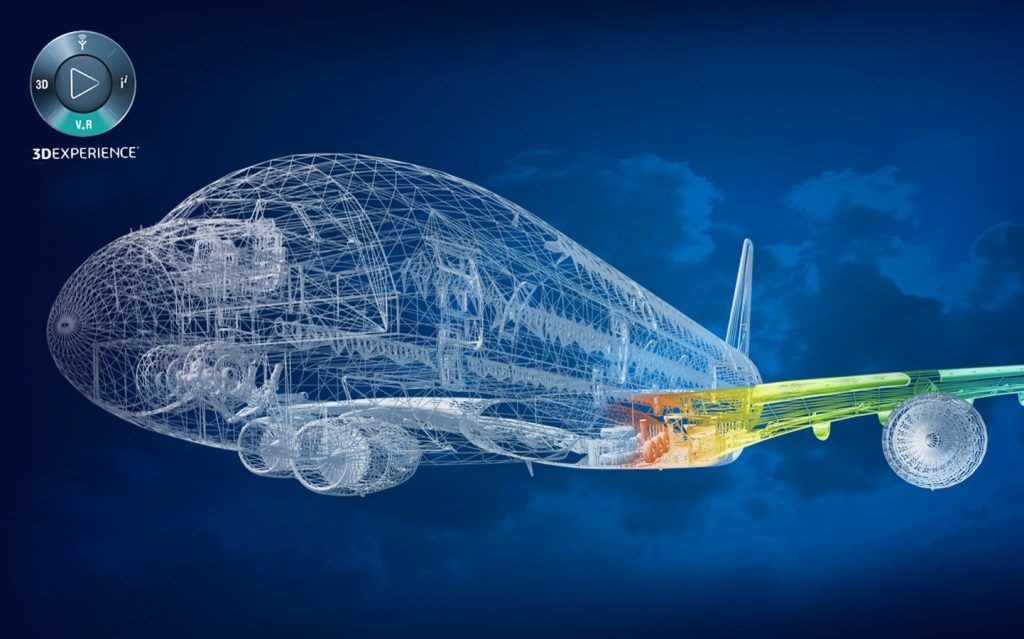

Curated 3D design and 3D printing solutions for every business, and every project

Optimize your product development processes with CAD, product lifecycle management (PLM), and additive manufacturing solutions tailored to meet your unique business needs and objectives for a faster, more reliable return on your product design investments.

Slide 3